HL is equipped with a comprehensive CAD/CAPP design system and has an annual capacity to develop more than 180 new products. The technology R&D center adopts a design model integrating 3D CAD design and CAE simulation analysis, supported by a unified R&D system that combines external testing, in-house testing, and customer road tests. In product design, HL applies its self-developed Bearing Parametric Navigation Design System and Intelligent Process Design System, enabling rapid completion of design documentation for various types of bearings. New products are managed under a PPQP lean management model and data management is realized through a PLM system.

In recent years, HL has focused on high precision, long service life, high reliability, high speed, low friction, and lightweight design as its core development directions. Significant breakthroughs have been achieved in areas including high-precision long-life bearings, high-precision non-adjustable bearings, pre-adjusted maintenance-free truck wheel hub units, passenger car wheel hub units, low starting friction torque bearings, high-speed bearings for new energy vehicles, shield tunneling machine cutterhead bearings, wind power gearbox bearings, industrial robot reducer bearings, self-lubrication technologies, pre-adjusted intelligent monitoring technologies for truck wheel hubs, surface modification technologies, and carbonitriding technologies.

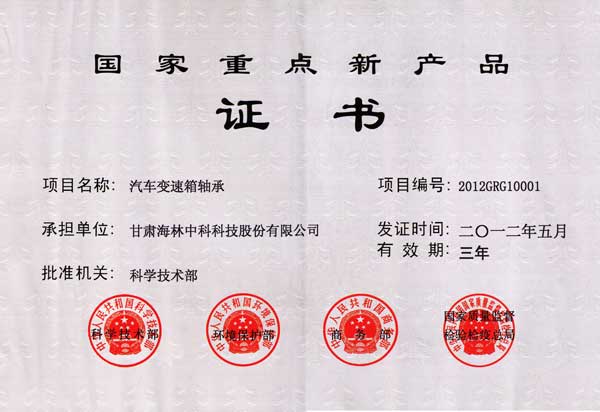

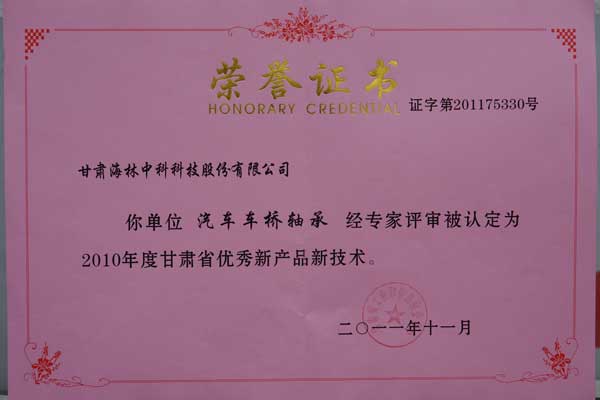

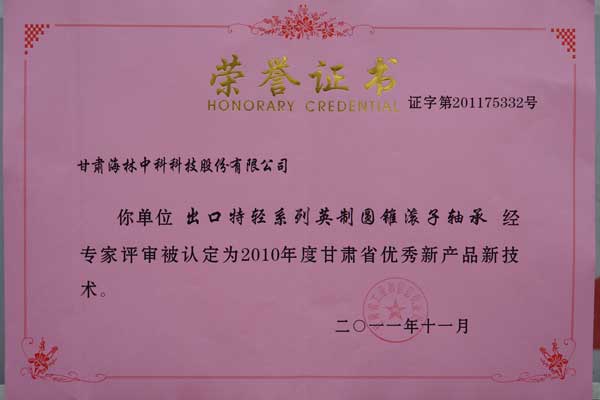

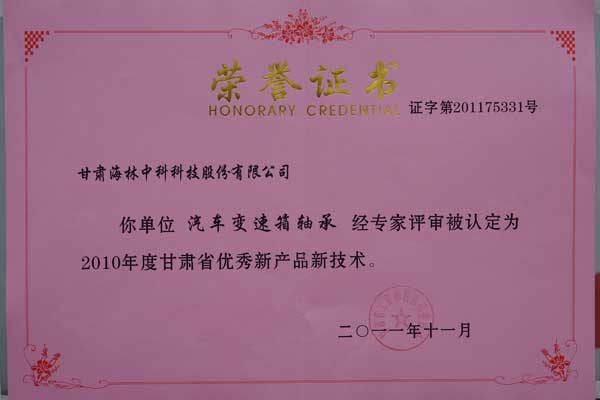

HL holds 98 patents and has participated in the drafting and formulation of three national standards. Six product series have been recognized as Excellent New Products of Gansu Province, among which one series was awarded National Key New Product, and five scientific and technological achievements have received municipal-level Science and Technology Progress Awards.

HL employs 162 full-time R&D personnel, including 6 with senior professional titles, 5 members of industry professional committees, 1 adjunct professor, 1 provincial leading talent, and 3 municipal leading talents. The high-performance bearing R&D innovation team has been recognized as one of the city’s first professional technical talent teams.

In recent years, HL has focused on high precision, long service life, high reliability, high speed, low friction, and lightweight design as its core development directions. Significant breakthroughs have been achieved in areas including high-precision long-life bearings, high-precision non-adjustable bearings, pre-adjusted maintenance-free truck wheel hub units, passenger car wheel hub units, low starting friction torque bearings, high-speed bearings for new energy vehicles, shield tunneling machine cutterhead bearings, wind power gearbox bearings, industrial robot reducer bearings, self-lubrication technologies, pre-adjusted intelligent monitoring technologies for truck wheel hubs, surface modification technologies, and carbonitriding technologies.

HL holds 98 patents and has participated in the drafting and formulation of three national standards. Six product series have been recognized as Excellent New Products of Gansu Province, among which one series was awarded National Key New Product, and five scientific and technological achievements have received municipal-level Science and Technology Progress Awards.

HL employs 162 full-time R&D personnel, including 6 with senior professional titles, 5 members of industry professional committees, 1 adjunct professor, 1 provincial leading talent, and 3 municipal leading talents. The high-performance bearing R&D innovation team has been recognized as one of the city’s first professional technical talent teams.